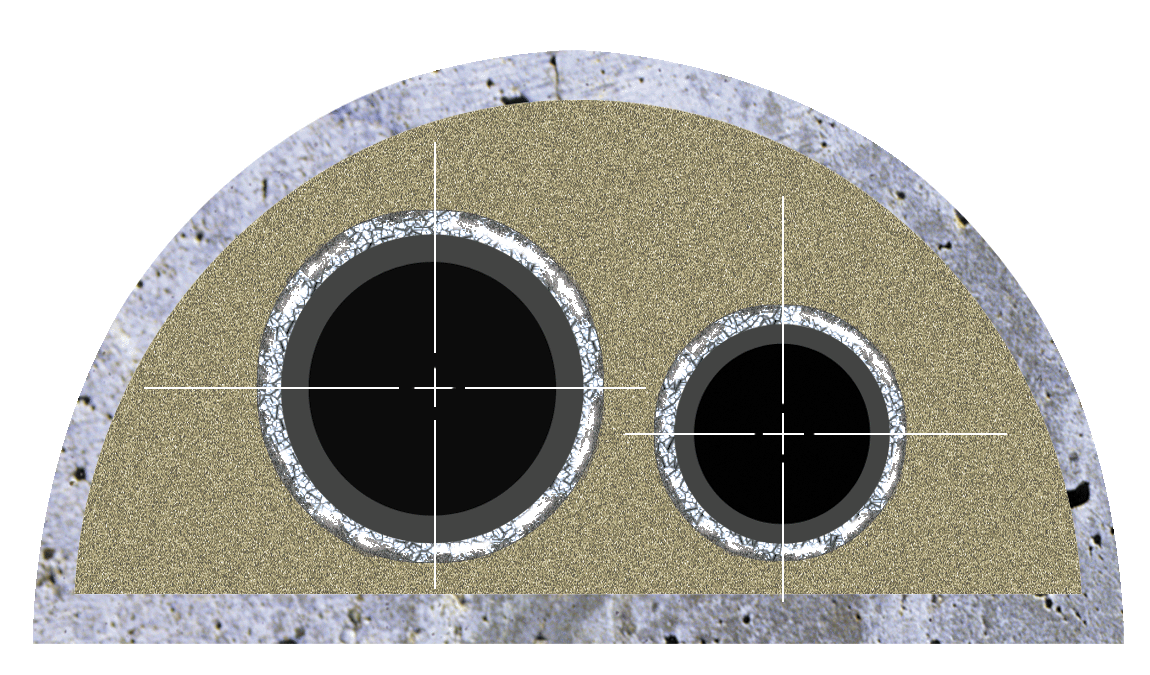

Buried high-temperature steam and hot water distribution systems throughout the world today often remain in service with insulation that has significantly deteriorated or disappeared over time. System owners and operators are often unaware of the level of degradation since the piping system is aged, buried and out of sight. Breaches in the outer conduits/casings along with the presence of an annular void between the outer casing and carrier pipe together will enable ground water intrusion which breaks down the binders of the existing insulation resulting in thermal inefficiencies and energy loss.

ConduFill® is a proven restorative process that reinsulates and enhances thermally-inefficient piping systems by injecting a rigid, high-temperature polyisocyanurate insulation into the annular space between the carrier pipe and the outer casing. Our patented technology is carried out while the system remains in service and is designed to withstand operating temperatures up to 400˚F (204˚C). In just 5 steps, TST will thermally restore aged piping systems through evaluation, design, access, injection and surface restoration.

1

Evaluate Piping System

2

Access Piping System

3

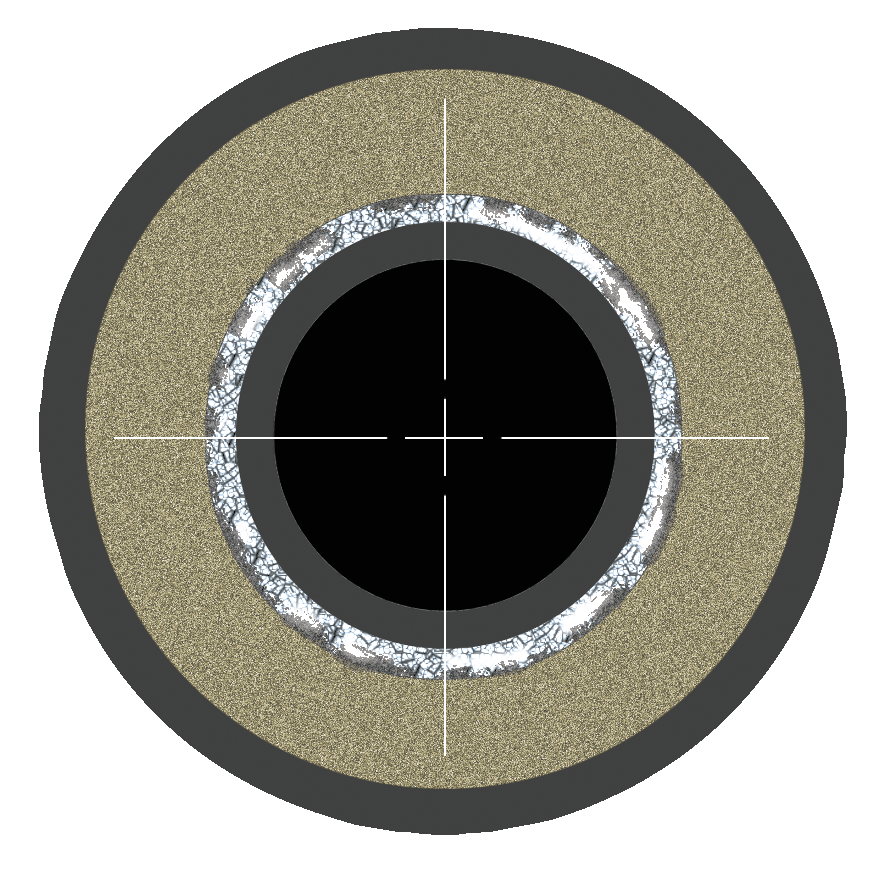

Inject ConduFill®

4

Restore Surfaces

Technical Data (HT-450)

Service Temperature

400°F (204°C)

K-Factor

.18btu-in/hr-ft2 -°F

Compressive Strength

16-17.5 psi

Density

3.0pcf

Closed-cell Content

95%+

Water Absorption

Less than 2%

Dimensional Stability

-0.20%

*The above data is based on ASTM testing of in-service ConduFill® samples. All samples were tested by an independent laboratory and have met or exceeded these values.

Benefits

The minute ConduFill® is injected into a buried piping system, energy savings and reduced fuel costs begin. Restoration usually results in a 40-90% heat loss reduction and an ROI of 2-5 years depending upon on energy costs.

The cost of excavating and replacing buried distribution piping ranges from $400 to $2000 per LF. ConduFill® is usually 20-40% of the cost of complete replacement.

ConduFill® will upgrade and repair the insulation thereby extending the life of the distribution system.

There is no need for shutdowns or outages. The piping system can remain in service throughout the entire restoration process.

The formulation expands 30 times its own volume to effectively fill the target void and to seal off breaches, cracks and holes that have developed in the outer casing over time.

Unsightly vapor is usually a sign of poorly insulated distribution piping. The vapor is eliminated as water can no longer get into the system due to the presence of ConduFill®.

Nearby utilities such as fiber optic, electrical and water lines can become damaged by the heat of nearby distribution lines. ConduFill® will eliminate this conflict and protect from further damage.

Accessing the piping system through small vacuum digs and manholes minimizes disruption of vehicular and pedestrian traffic.

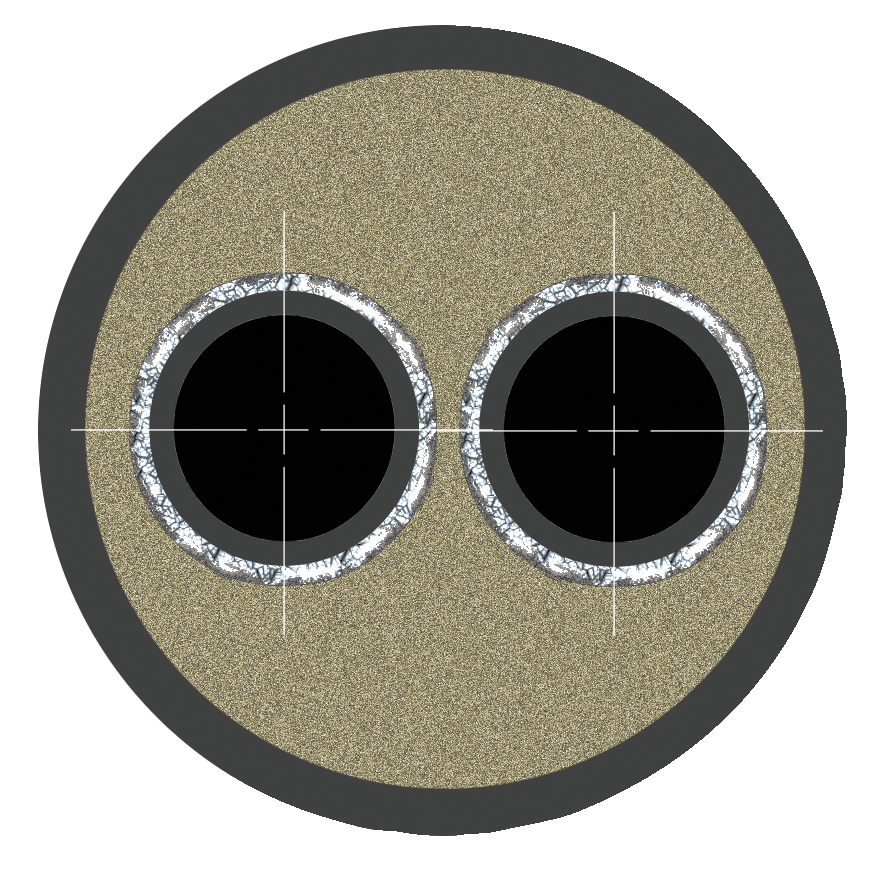

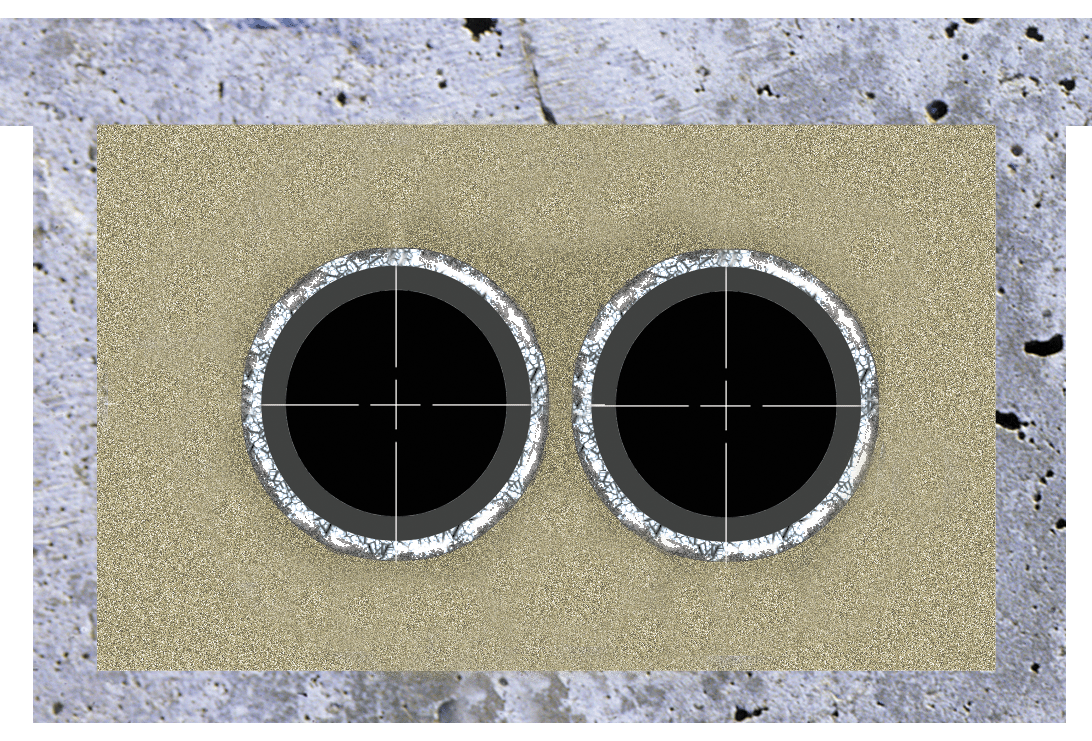

Common Types of Buried Piping Systems