RIC-2110PYRO

Recommended for use in flood-prone manholes, tunnels, vaults & pits on:

Valves ∙ Piping ∙ Flanges ∙ Expansion Joints ∙ Y-Strainers

Why Pyrogel®?

Pyrogel® XT-E insulation is highly recommended for use inside removable insulation blankets that are fabricated for pipe and fittings in flood-prone manholes, pits, vaults, tunnels and other confined spaces. In fact, we believe its hydrophobic characteristics are unmatched in the insulation industry. Aside from its ability to repel water, Pyrogel® XT-E is thinner and lighter than most other conventional insulations making removal and replacement of our RIC-2110PYRO insulation blankets much easier and safer for personnel.

What thickness is right for removable insulation blankets?

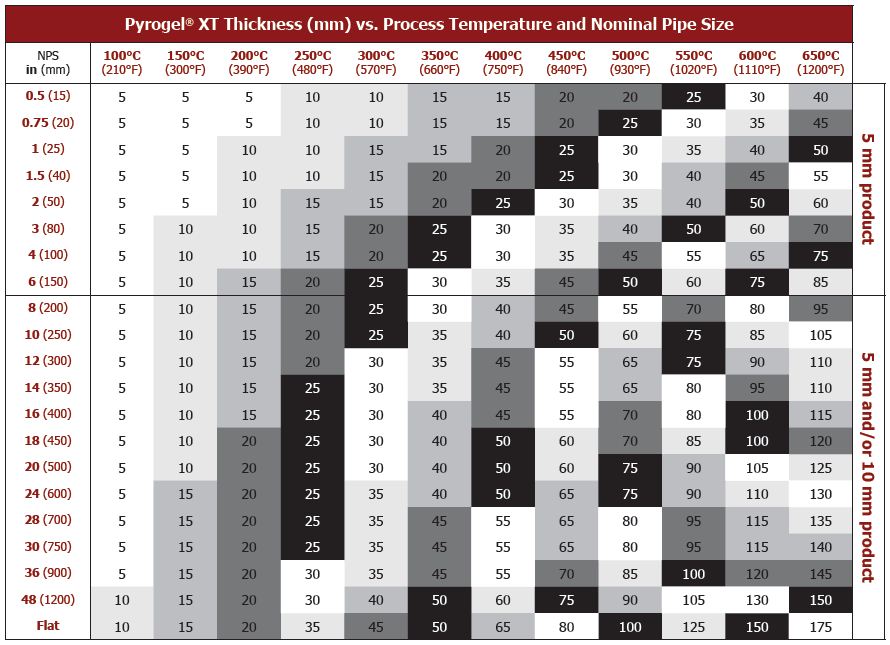

Many clients ask what thickness we recommend for Pyrogel XT-E inside removable insulation blankets: 5mm, 10mm, 15mm or 20mm. The answer to that question depends mostly on the operating temperature and somewhat on the nominal pipe size (NPS). Removable insulation blankets for pipe and fittings with a NPS of less than 2” are usually limited to a 5mm thickness as anything thicker is too difficult to fabricate and will lack heat retention. Since rolls of the product are available in thicknesses of 5mm or 10mm, insulation blankets requiring 15mm or 20mm are fabricated with two layers inside and then anchored through the outer jacketing to prevent movement.

For more information, check out Aspen Aerogel’s chart below which illustrates recommended thicknesses of Pyrogel® XT-E based on pipe temperature and nominal pipe size:

Material Specifications

Inner/Outer Jacket

13.5 oz. TCI LFP-2110 CrossFilm™ PTFE*

*This flexible, tear resistant 100% PTFE jacketing is proven to be unaffected by complete immersion in wet environments. The use of Pyrogel® XT-E, a 100% hydrophobic insulation, allows us to deliver an industry-leading, high thermal performance RIC while resisting the absorption of water. The use of Pyrogel® XT-E also produces a thinner and lighter RIC which makes for much easier removal and replacement by personnel.

600˚F

0.009” (0.23mm)”

13.5 oz./yd2

Grey & Royal Blue

Core Insulation

Pyrogel® XT-E aerogel insulation (hydrophobic) *

*This flexible, tear resistant 100% PTFE jacketing is proven to be unaffected by complete immersion in wet environments. The use of Pyrogel® XT-E, a 100% hydrophobic insulation, allows us to deliver an industry-leading, high thermal performance RIC while resisting the absorption of water. The use of Pyrogel® XT-E also produces a thinner and lighter RIC which makes for much easier removal and replacement by personnel.

1200˚F

5mm, 10mm, 15mm & 20mm

12.5 lb/ft3

.24 @ 300˚F, .44 @ 500˚F & .62 @ 600˚F

Fabrication & Design Requirements

- RICS are custom-fabricated and will conform to the configuration of the pipe or fitting in a manner that maximizes heat retention.

- All RICs are designed so that bending or folding will not be necessary for removal and replacement.

- Machine stitching is used to fabricate all RICs. Stitching is double straight-stitched, 8-10 stitches per inch and parallel stitch rows are spaced 1/8” to 2” apart. All thread at seams is Teflon® coated for resistance and longevity.

- All seams are inside seams meaning that RICs are sewn inside-out and then turned correct side-out before insertion of the insulation core.

- All closing seams are sewn on the exterior of the RIC.

- All parting seams are installed at the low point of each RIC to allow for drainage without the use of drains, weep tubes or grommets.

- All RICs include openings for protrusions from the body such as pipes, packing glands, supports, instrument lines and other obstacles.

- 3” wide flaps at terminal ends are provided to overlap and to secure to adjacent RICs or conventional insulations.

- All terminal end flaps will be the same material as the specified jacketing material with yellow Nomex® draw cords for cinching and securement.

- All straps fabricated for securement will be the same material as the specified jacketing and will include a double buckle or D-ring buckle.

- All straps are placed 2” back from parting seams and on 6” centers.

- All straps are fabricated with an additional piece of jacketing material sewn inside the jacket to provide extra strength at the point of securement.

- Thickness of the core insulation is determined by pipe/fitting temperature or size.

- To prevent insulation movement within the RIC, the insulation core is secured to both the inner and outer jacketing with stainless steel 304 quilt pins and washers.

- Black fire-retardant Velcro® is used to fasten the securement strap to the jacket surface after the strap passes through the double buckle D-ring.

- Each RIC is identified by a 3.5” X 1.5” stainless steel ID tag embossed with information such as RIC #, type/size of item being covered, location of the item as well as any other pertinent information that is requested by the owner/contractor.

- TST recommends covering most valve bonnets and leaving packing glands exposed.

- RICs for most valve types are designed so that each bonnet section is sewn to the body of the valve. For larger valves, the RIC may be fabricated in two sections, each section containing one-half of the valve body and bonnet.