Mechanical Pipe Insulation

Turnkey Project Execution

TST provides turnkey repair, removal and installation of mechanical insulations within federal, commercial, institutional, industrial and hospital facilities throughout the U.S. Most often the application of mechanical insulation goes hand-in-hand with the installation of our custom-made Removable Insulation Covers when working in areas with steam, condensate, hot water, chilled water, cryogenic or process piping. We are often contracted to install mechanical pipe insulation and Removable Insulation Covers simultaneously so that transitions from one to the other are precise and will maximize heat retention.

Turnkey Project Execution

1

Survey

All bare and poorly insulated pipe, fittings and equipment are identified and a detailed report containing candidates for removal and replacement of conventional pipe insulation is generated. Site conditions are noted so that we can recommend appropriate jacketing and insulation materials. Projected energy savings and ROI can also be provided at this stage upon request.

2

Measure

Upon award, TST mobilizes to the site to I.D. and measure the scope and to create insulation material lists. Client PMs are welcome to accompany our team at this stage to be certain that all items and areas are addressed.

3

Install

Our experienced team returns to the facility to remove and install mechanical pipe insulations and required jacketing on pipe, fittings and equipment.

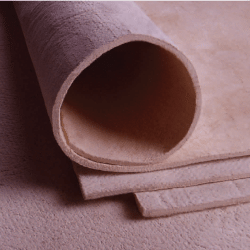

Mechanical Pipe Insulation Designed for Your Facility’s Environment

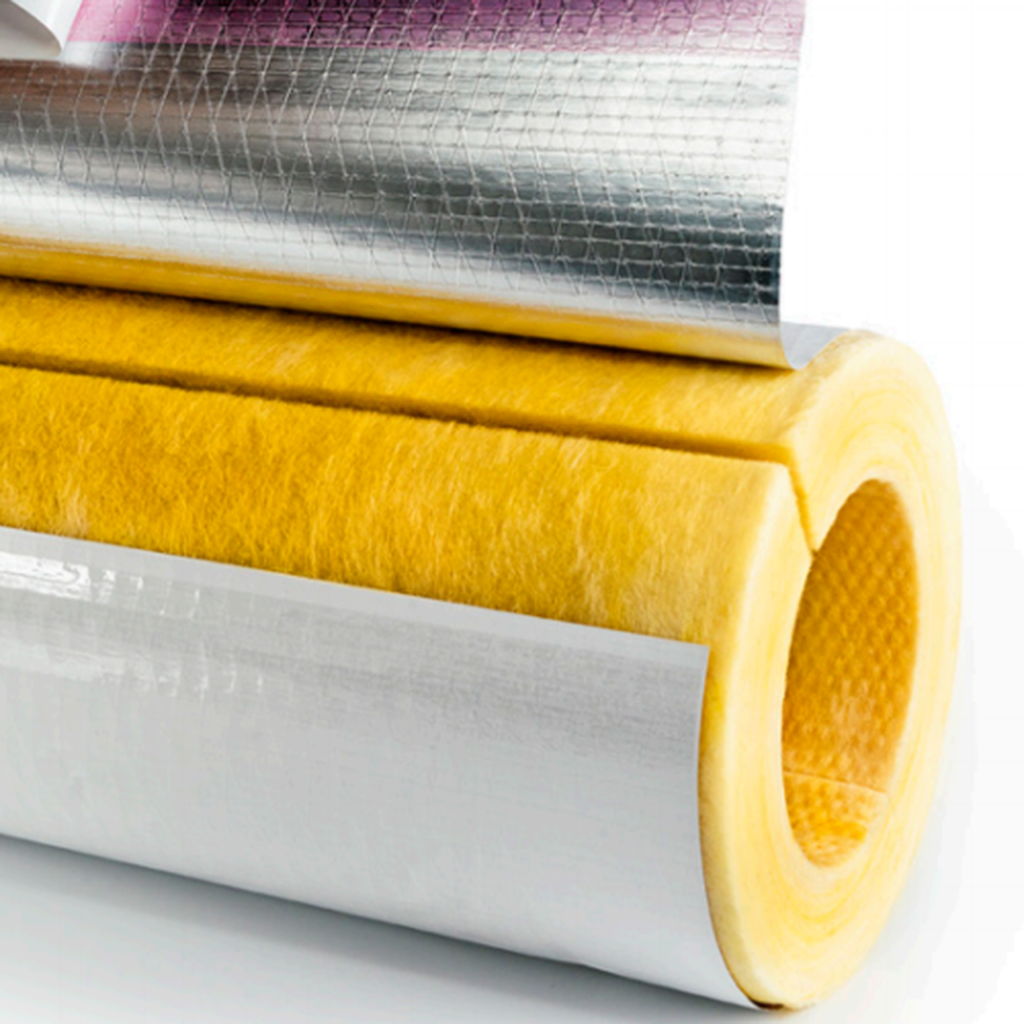

Fiberglass Pipe Insulation

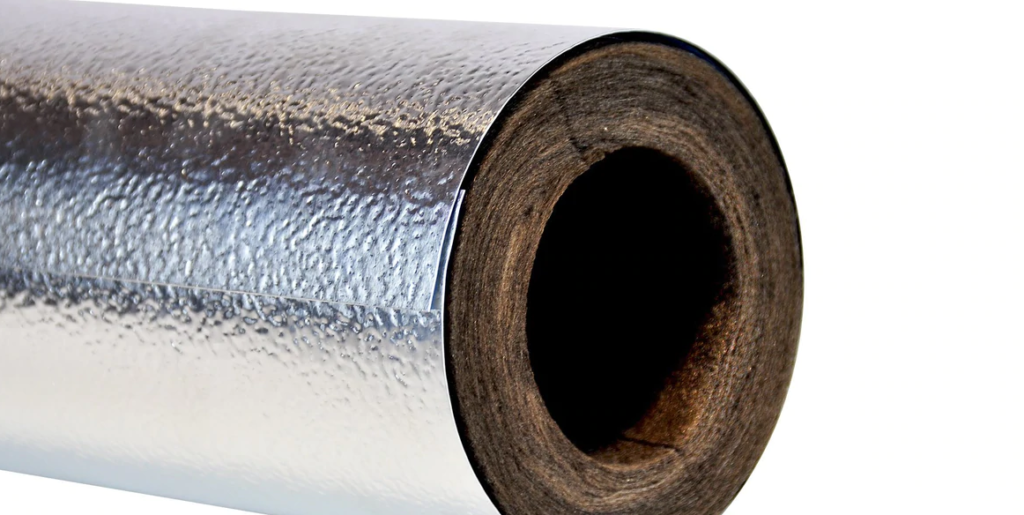

Mineral Wool Pipe Insulation

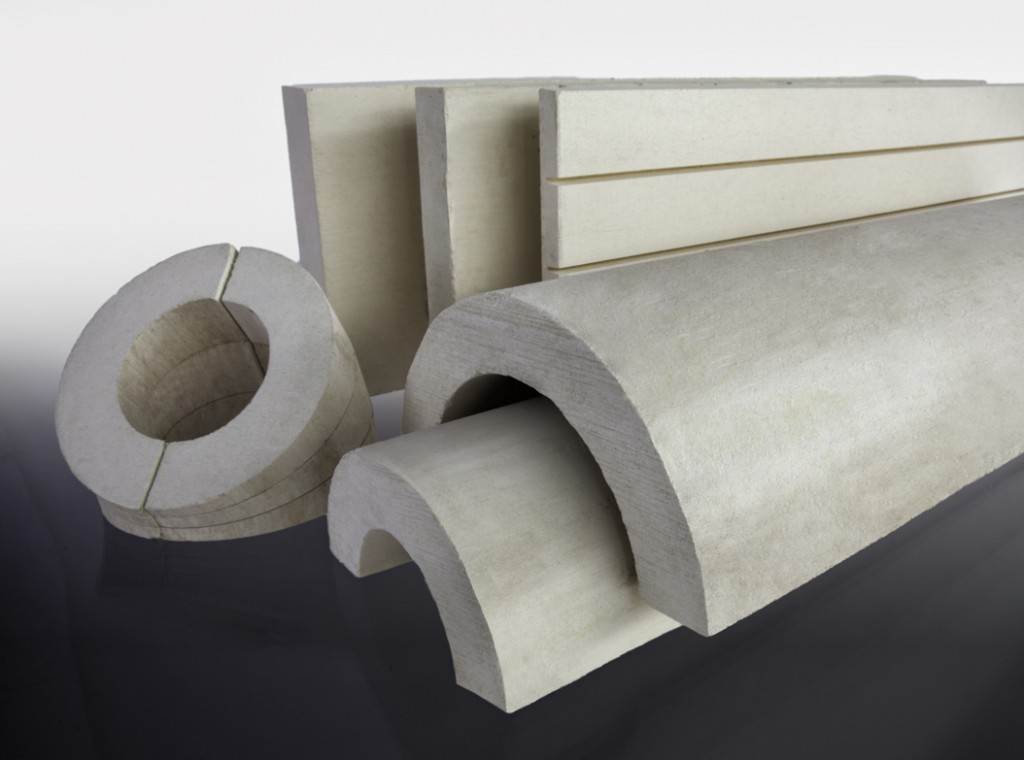

Calcium Silicate Pipe Insulation

Armaflex Pipe Insulation

Pyrogel® Pipe Insulation

PVC Fitting Covers

PVC Jacketing